At Pranjal Projects Pvt. Ltd., we offer a comprehensive range of welding wires designed for superior performance in industrial and structural applications. Our state-of-the-art, fully automated manufacturing plant ensures that our MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and SS (Stainless Steel) wires meet the highest industry standards, providing reliable solutions for various welding processes.

Download Brochure

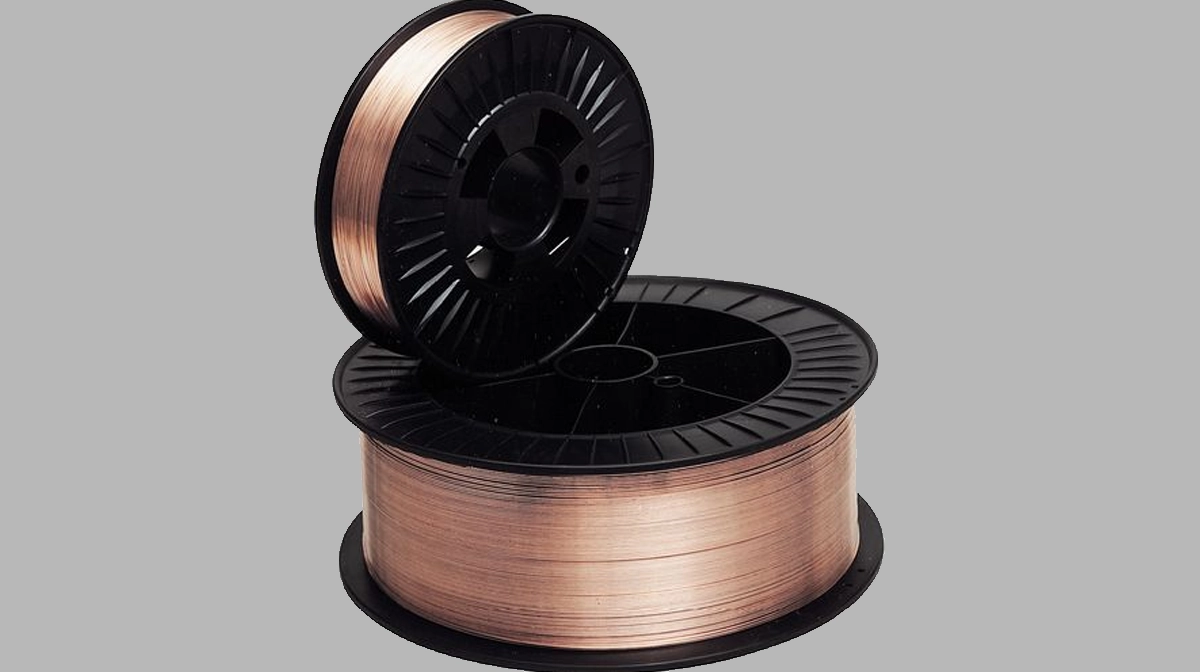

MIG Wires

Applications: MIG wires are widely used in industries such as shipbuilding, automotive manufacturing, heavy equipment, and steel structures. They are particularly suited for welding carbon and low-alloy steels.

Technical Specifications:

- Diameter Range: 0.80mm – 1.60mm

- Wire Type: ER70S-6, ER70S-3

- Tensile Strength: 620 – 710 MPa

- Yield Strength: 500 MPa min

- Elongation: 22% min

- Shielding Gas: 100% CO₂ or Argon + CO₂

- Spool Weight: 5kg, 15kg, or 20kg

- Coating: Copper-coated for superior conductivity and arc stability

TIG Wires

Applications: TIG wires are ideal for welding pressure vessels, boilers, aerospace components, and automotive parts where precision and reliability are paramount.

Technical Specifications:

- Diameter Range: 1.00mm – 3.20mm

- Wire Type: ER70S-2, ER308L, ER316L

- Tensile Strength: 580 – 750 MPa (depending on grade)

- Yield Strength: 420 MPa min

- Elongation: 30% min

- Surface Finish: Bright finish for optimum feedability

- Shielding Gas: 100% Argon

- Packaging: Available in straight lengths of 1 meter or 5kg tubes

Our Welding Wire Offerings

- CO2 MIG Wires: Our CO2 MIG wires are designed for high-performance welding in various industrial applications. They provide excellent arc stability, low spatter, and high deposition rates, making them ideal for heavy-duty welding tasks.

- TIG Wires: TIG wires are essential for precision welding applications where control and high-quality welds are paramount. Our TIG wires ensure smooth arc performance and superior weld quality, suitable for a wide range of metals and alloys.

- SS Wires: Our Stainless Steel (SS) wires are engineered for corrosion resistance and strength, making them ideal for welding stainless steel and other alloys. These wires offer excellent weldability and are suitable for applications in industries such as food processing, chemical processing, and marine environments.

Manufacturing Capabilities

Our advanced manufacturing facilities are equipped with the latest technology to produce MIG, TIG, and SS wires that adhere to the strictest industry standards:

- Precision Drawing: Our precision drawing process ensures consistent wire diameter and a smooth surface finish, crucial for reliable welding performance.

- Copper Coating: We apply copper coating to MIG and TIG wires to enhance corrosion resistance and improve electrical conductivity, contributing to better welding outcomes.

- Spooling & Packaging: Our spooling and packaging processes ensure that wires are properly wound and securely packed to prevent damage during transport and storage.

Quality Assurance

We adhere to rigorous quality control processes to ensure that our welding wires meet or exceed industry standards:

- Chemical Composition Testing: We verify the precise chemical composition of each batch to ensure consistency and quality.

- Tensile & Yield Strength Testing: Our testing confirms that our wires meet the required mechanical properties for strong and durable welds.

- Dimensional Inspections: We conduct dimensional inspections to ensure that all wires meet the specified diameter and tolerance requirements.

Customization & Client Support

Understanding that different welding applications require specific wire characteristics, our engineering team works closely with clients to develop custom MIG, TIG, and SS wires that meet their unique needs. We provide full support from product selection to post-sale service, ensuring that our clients receive the best possible solutions for their welding requirements.

Why Choose Pranjal Projects Pvt. Ltd.?

With our commitment to quality, innovation, and customer satisfaction, Pranjal Projects Pvt. Ltd. is your trusted partner for high-performance welding wires across multiple industries.